Tubular Positive Additive

BrandSSRL

-

Product is not available

- Price upon request

-

-

We are reckoned entity of this domain engaged in offering an enhanced quality Tubular Positive Additive.

Other Details:

- The effect of addition of Tubular Positive Additive shows when the tubular electrodes were cycled, the capacity of the ground positive active material was gradually restored

- Energy density of Active material & Cycle life increased as a function of the contact of Tubular positive additive

- The active material on the positive plates is mainly a mixture of lead oxide and Red Oxide

- In regular formulation, some of the active material will be underutilized due to non porous structure, Lack of Tetra basic lead sulfate Crystals Structure

- In order to achieve a porous structure with a high surface area for the electro-chemical process, the Tubular positive plates undergo a high temperature curing process to transform the lead oxide and lead sulfate into Tetra basic lead sulfate

- There is however limitations due to the large size of the Tetra basic lead sulfate crystals

- This can lead to a major disadvantage with Tetra basic lead sulfate namely a prolonged and higher electrical energy requirement for the formation of the positive plates and less surface area for the electro-chemical processes

- We suggest that after dry blend filling dip Tubular Positive electrodes in 1

- 150 Specific gravity of H2SO4 and then cured at 85 deg C for 4-5 hours in oven to form tetra basic Lead Sulfate crystals and alpha PbO2

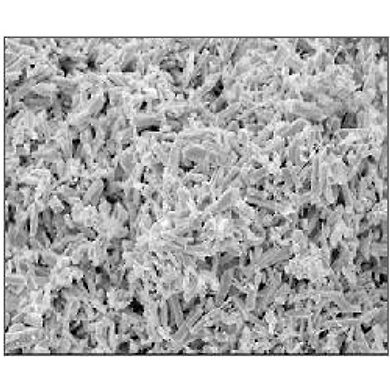

- The tetra basic lead sulfate has sizes up to 3-20 micron

- Tubular positive additive leads into Uniform crystal size and increase in specific surface area

- The formation of a homogeneous tetra-basic sulfate crystal structure in the Tubular positive plates of lead-acid batteries is well known to offer significant electrochemical improvements in battery performance in respect of improved cycling and battery life

- By addition of Tubular Positive Additive a number of crystal seed sites are created, this leads to a large number of relatively even tetra-basic lead sulfate crystals

- It has been found that only a relatively short treatment of 3 to 4 hours is required to fully develop the crystal structure in the oven

- Without addition of Tubular Positive Additive in the blend Conventional method of Oven Chamber Heat Treatment Tetra basic curing process leads in the appearance of relatively large Tetra basic lead sulfate crystals

- Up to now it is has not been possible to control precisely the size of the final Tetra basic lead sulfate crystals

- The uncontrolled Tetra basic crystal growth leads to a reduction in the active surface of the plate

- A high specific surface area is demanded for good battery performance with respect to high current discharge capability

- The main feature of the Tubular Positive Additive is that the size of the final Tetra basic lead sulfate crystals can be controlled within the range from 4 to 15 µm

Minimum Order Quantity1

Accept Small Orders Yes

-

Reviews ()

Write a Review